Our decarbonisation transition plan is a commitment towards achieving net-zero emissions

We recognise that there are risks related to the transition to a lower-carbon economy that BW LPG will be part of as a maritime and energy stakeholder. We choose to be innovative and as we explore alternative fuels to propel our vessels into a greener future and expand along the value chain, we ensure that sustainability is embedded at every stage. This approach guides our actions, from internal operations to industry-wide collaboration, as we navigate the challenges of decarbonisation.

Evaluation

This is a dedicated evaluation based on the guidance provided by the Task force for Climate Related Disclosures (TCFD) and has been incorporated within our Enterprise Risk Assessment.

| Time Frame | Potential Risks | Potential Impact | Potential Mitigation | |

|---|---|---|---|---|

| Policy and Legal | Short to Mid (0 - 5 years) | Shipping will be impacted by the implementation of climate market- based measures. Evolving regulatory frameworks such as the IMO revised Decarbonisation strategy, IFRS sustainability reporting standard, SEC climate rules and European Union's (EU) Green Deal demand more onerous reporting requirements for emissions. Additional climate-related clauses in charter-hire agreements have to be crafted with caution. Regulatory limitations on use of conventional fossil-fuel based bunkers would also affect current bunkering operations. | Using conventional fossil-based fuels will be more expensive as a result of carbon levies such as the EU Emissions Trading Scheme (EU ETS) to be effective from 2024. In order to comply with emissions laws, ships may slow down, restricting service capacity. It could be necessary to retire assets early if they are unable to comply with requirements. Charter-hire charges could increase to cover rising operating costs and new technological investments. | Setting up of internal workflows and engaging expertise to administer the participation in carbon markets and work on reducing cost exposure. In the long run, early adoption of next-generation vessel technology and industry cooperation for the creation of a low-emissions fuel supply chain can be beneficial and prevent the early retirement of assets. |

| Technology | Short to Long (0 - 5+ years) | Rapid developments in technology will render certain systems obsolete. The needs and requirements of internal and external stakeholders could be delayed or not met, resulting in inefficiencies in operations and potential non- compliance with regulations. | Existing equipment may be prematurely retired. This may result in higher capital expenditures for upgrading IT infrastructure, introducing new technologies, and investments in user training. | To advance our knowledge in new technology, we conduct thorough research and analysis before making any investments in next- generation technology. This can also include risk and impact analysis on current procedures and business function requirements. |

| Market | Long (5+ years) | Changes in market preference where LPG supply and demand may shift as the world switches to cleaner burning energy and also as a result of increased geopolitical tensions. Global VLGC fleet capacity could fluctuate due to a combination of new regulations, shipping inefficiencies and orderbook. | Reduction in import/export volumes and oversupply of VLGC fleet could lead to a decline in freight rates. The price of LPG may increase as a result of unfavourable regulatory changes or a decrease in supply. | Industry knowledge sharing and network to support LPG as a viable transition fuel to more sustainable energy sources. Our Product Services division helps to support commercial utilization on our vessels. Taking the lead in low-carbon shipping and reviewing trading patterns can reduce inefficiencies. Investments along the value chain to support LPG supply and demand into countries. |

| Reputation | Mid to Long (2 – 5+ years) | Stakeholders are increasingly concerned about the industry’s long- term financial viability due to its pollutive nature. | Non-compliance with regulations and indifference to stakeholder expectations can impact our operations and reduce the trust stakeholders have in us. | We constantly aim to improve our fleet efficiency and ensure regular maintenance to meet upcoming regulations. To uphold service quality and meet changing stakeholder needs, research and development (R&D) of next- generation technology for low-zero carbon vessels is necessary. |

Regulatory shifts are expected to be the main driver of decarbonisation, BW LPG is proactively monitoring developments and will conduct a comprehensive assessment of its activities within scope before the mandated timeline.

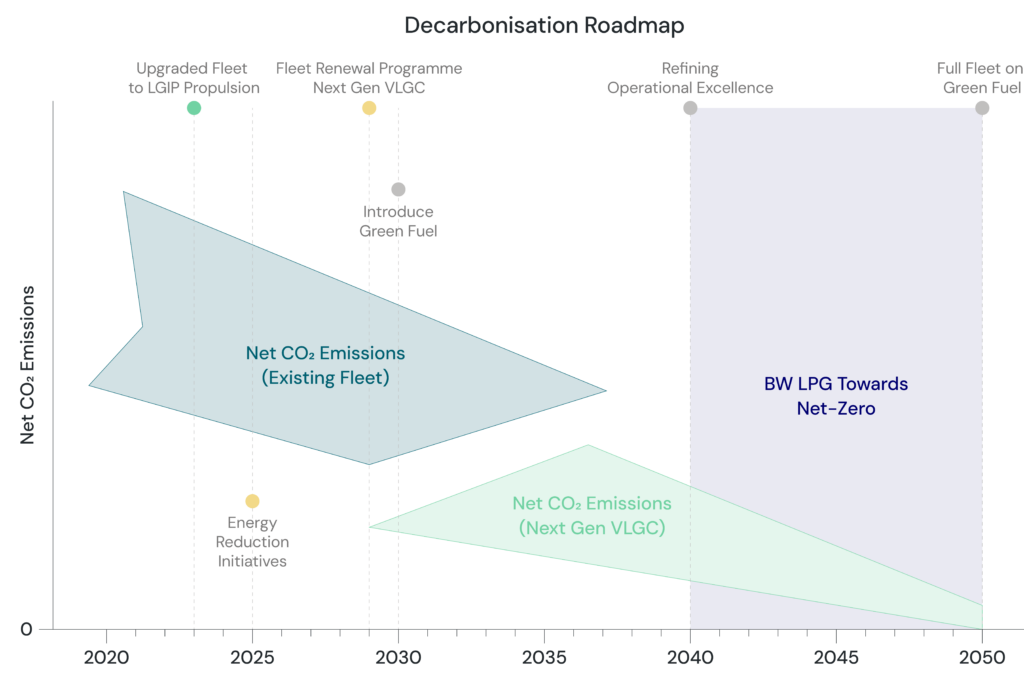

Decarbonisation Roadmap

At BW LPG, our commitment to decarbonisation requires a substantial shift in our operations. We’re actively reviewing our long-term roadmap to explore various strategies and keeping updated on new technologies and alternative fuels. We collaborate with stakeholders and industry groups such as the Getting to Zero Coalition, as well as leverage on decarbonisation initiatives within the broader BW Group.

With Shipping at the core of our business activity, the Decarbonisation roadmap sets out milestone targets and initiatives we are working towards for our internal technically managed fleet.

Exploring Alternative Fuels

Scaling the use of near-zero/low-GHG emissions fuels and alternative propulsion technologies

LPG Dual-Fuel Propulsion Technology

BW LPG is contributing towards advancing technology that will allow us to decarbonise and maximise the value of an asset with a 20-year lifespan as we transition towards zero-carbon solutions. Read more about the benefits of LPG propulsion here.

2020 marked the start of our project to retrofit 15 of our vessels with pioneering LPG dual-fuel propulsion technology, a project which began in early 2016 as part of our plans for a more sustainable and efficient ship design for the future.

In collaboration with MAN Energy Solutions, Wartsila, DNV and Isle of Man flag state, we pioneered the technology that allows us to use both conventional fuels and LPG – a cleaner marine fuel – to power our vessels. Our commitment to retrofit 15 of our VLGCs with LPG dual-fuel propulsion engines represents an investment of over US$130 million. The retrofitting program was completed in 2022.

These vessels emit up to 97% less sulphur and 20% less nitrogen than heavy fuel oil. They reduce emissions of particulate matter by up to 90% and carbon emissions by up to 15%. Although it requires significant upfront investment, the returns are positive environmentally, economically and operationally.

Embracing Innovation

Embracing innovation, we are actively exploring and investing in alternative fuels. This includes a shift towards cleaner and more sustainable energy sources that can power our vessels, reducing dependence on traditional, carbon-intensive fuels. Our Nh3 (Ammonia) Task Force aims to explore viability in the ammonia market, including but not limited to ammonia as a marine fuel, ammonia shipping onboard our vessels, export projects, and potentials of blue and green ammonia.

We see potential in the ammonia market due to parallels in the LPG shipping segment. However, there are several concerns that need to be addressed before it becomes a viable option. In this regard, we are staying abreast of changes and developments in the alternative fuel space.

| Type of fuel | Pros | Cons |

Biofuels |

|

|

Hydrogen |

|

|

Ammonia |

|

|

Methanol |

|

|

Synthetic Diesel |

|

|

Next-Generation Vessels with Cutting-Edge Technologies

Focusing on technological advancements and digitisation

Our commitment to sustainability extends to the development of next-generation vessels. These vessels will incorporate state-of-the-art technologies aimed at enhancing operational efficiency while minimising environmental impact. By investing in advanced vessel designs, we aim to lead the industry in adopting eco-friendly practices and setting new standards for maritime sustainability where we are committed to the goal that by 2030, we will not have any newbuilding that cannot achieve net-zero emissions during its lifetime.

| Potential Next-Generation Technologies | Highlights |

Carbon Capture

| Carbon Capture, Utilisation and Storage (CCUS) is considered to be a technically and economically viable method to lower GHG emissions from the combustion of conventional fuels. However, current CCUS methods cannot be used on ships due to the impact on the vessel’s performance. |

Rotor Sails

| Could allow a vessel to maintain the same speed with reduced engine power or increased vessel speed with the same engine power. However, intermittency could disrupt daily practices and operations of vessel |

Batteries

| More economical and environmentally friendly approach to power vessels removes the need to constantly generate power; reducing the strain on vessel systems. But long freight distance makes access to charging infrastructure enroute a necessity; and developments are at a nascent stage. |

Air Lubrication Systems

| The air lubrication system reduces resistance between the sea and the vessel’s hull, increasing the vessel’s energy efficiency as a carpet of bubbles coats the full flat bottom of the vessel. Despite easy installation on new and existing vessels, high airflow rate is required to maintain the air layer and this works best on flat and horizontal sections of the hull. |

Fuel Cells

| Fuel cells are an alternative to batteries. However, conventional hydrogen fuel cells are limited in application as storage remains a big challenge. Alternatively, hydrogen can be stored in light chemicals such as ammonia and methanol where they are good indirect hydrogen storage materials and will not release carbon when used. |

It is imperative that we optimise our internal processes with automation and digitalisation. To enhance operational and demand efficiency, BW LPG employs digital solutions for real-time navigation and route adjustments, utilising weather and sea current data. These solutions enable the company to optimise vessel routes, minimising fuel consumption and voyage durations.

All internally managed vessels are equipped with SMARTShip technology onboard that enables real-time data transfers between ship and shore. Together with other initiatives such as smart weather routing, we actively reduce fuel consumption which not only means lesser emissions, but also greater savings.

Collaborating with Peers

Active Collaboration and Expansion Along the Value Chain

Sustainability is not confined to our immediate operations; it is deeply entwined in everything we do. We are expanding along the value chain and integrating sustainable practices at every stage. This includes responsible sourcing, efficient logistics, and eco-friendly distribution methods. Our aim is to ensure that sustainability is embedded across our entire business ecosystem. We continue to explore the best combinations of technology and fuels for net-zero emissions in LPG shipping. Collaboration is the way forward – by working with partners such as engine manufacturers, environmental solution providers and fuel suppliers, we can progress towards a net-zero carbon future together.

LPG Bunker Supply Contract

Collaboration is a cornerstone of our sustainability strategy. We actively engage with industry players, forging partnerships and alliances that amplify our collective impact. One practical example is in the securing of LPG as fuel for our LPG-powered vessels. Our retrofitted VLGCs need LPG bunker supply contracts. There is a need to establish new terms with customers, suppliers and oil majors to build the LPG bunker supply network. We made progress on this front and had our first bunker fuel agreement with ADNOC in 2023.

Getting to Zero Coalition

BW LPG is pleased to be a signatory to the Getting to Zero Coalition, an alliance of over 120 companies within the maritime, energy, infrastructure and finance sectors, supported by key governments and intergovernmental organisations. The Getting to Zero Coalition is a partnership between the Global Maritime Forum, the Friends of Ocean action, and the World Economic Forum.

Training Our Employees

Understanding our role in the global energy transition

At BW LPG, employees on shore and at sea understand that we have a role to play in reducing our environmental impact form operations, and the imperative that we evolve and transition towards more sustainable practices.

By keeping employees informed about the latest advancements and strategies in decarbonisation, organisations can inspire a collective commitment to find creative solutions and adopt cutting-edge technologies. We encourage employees to actively contribute to the organisation’s decarbonisation goals, and one way we are doing so is to provide training on the maintenance and optimal usage of low-GHG emissions propulsion systems, and ensuring the longevity and efficiency of our dual-fueled LPG vessels.